IONClean HL

- General

- Detail

- Technical Data

- Downloads

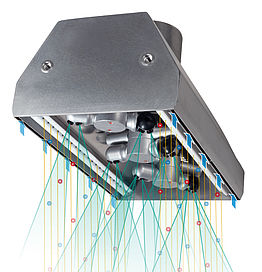

The cleaning hood IONClean HL is equipped with 2 ionizing bars, type SS 1/2". They neutralize the static load before and after the cleaning process. Rotating nozzles are installed between the ionizing bars to lift contamination off the surface. The particles are removed by means of suction cleaning. The cleaner performance is defined according to the customer specific application.

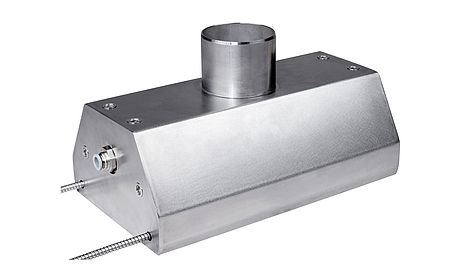

A specific power supply unit is mandatory: A2 A4S

Cleaning hoods of stainless steel (V2A) are used in the food industry, electronics-semiconductor industry, medical engineering and in the pharmacy.

When it is about to integrate the cleaning result into packaging processes or production processes, the cleaning hoods of the company Ziegener + Frick work effectively and economically.

- Non-contact cleaning

- Rotating nozzles

- Improved cleaning results

- Ionization of soil particles

- Extraction of soil particles

- System Solution

| Housing Material | V2A |

| Active width | From 1000 mm |

| Grid width | 100 mm |

| Overall width | Active width + 4 mm |

| Dept | 180 mm (+ rod 35 mm) |

| Height | 160 mm |

| Rotary nozzles | Variable subj. to application |

| Vacum aspiration | Dust collector D = 80 mm, special "Jacob" pipe option |

| Voltage | 2 x 4.0 kV or 2 x 5.0 kV |

| Pressureized air | Rotary nozzles 1 + 10 mm or 1 x 12 mm |

| Acoustic noise | 72 db (A) |

Download

|

|

IONClean_HL_Datasheet_en.pdf | 3 MB |

|

|

IONClean_HLOPeratingmanual_en.pdf | 8 MB |